Replacing the original air duct and a fan on 3D printer (Sovol SV06)

If you’re reading this on fediverse and the layout is off, here’s the link to the original blog post with a nice text & pictures layout.

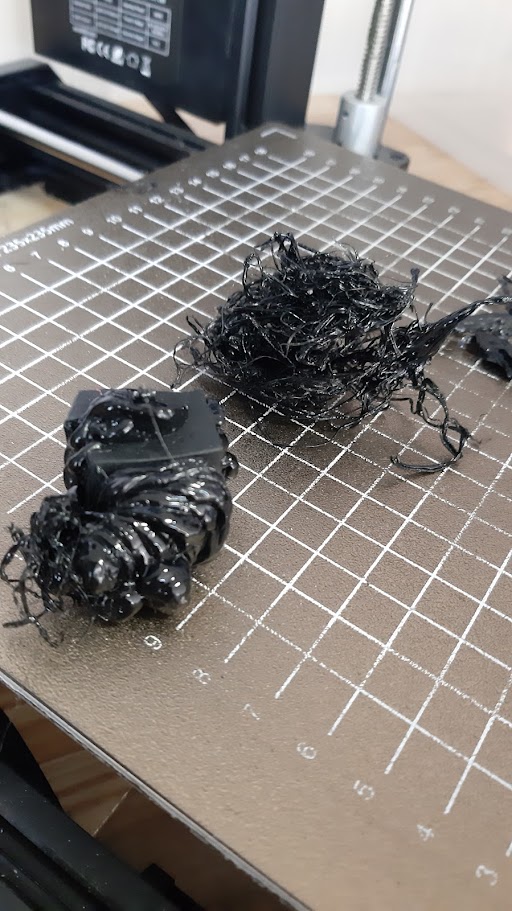

It started with this ‘blob of death’. I was printing with nylon, when it happened. Nylon filament is a PITA. It was good when I unpacked it and the next day. Then it caught so much moisture that printing was almost impossible. I even bought a filament dryer to dry it with no success.

The prints had gaps (because of exploding water droplets) and then the blob formed when I was away.

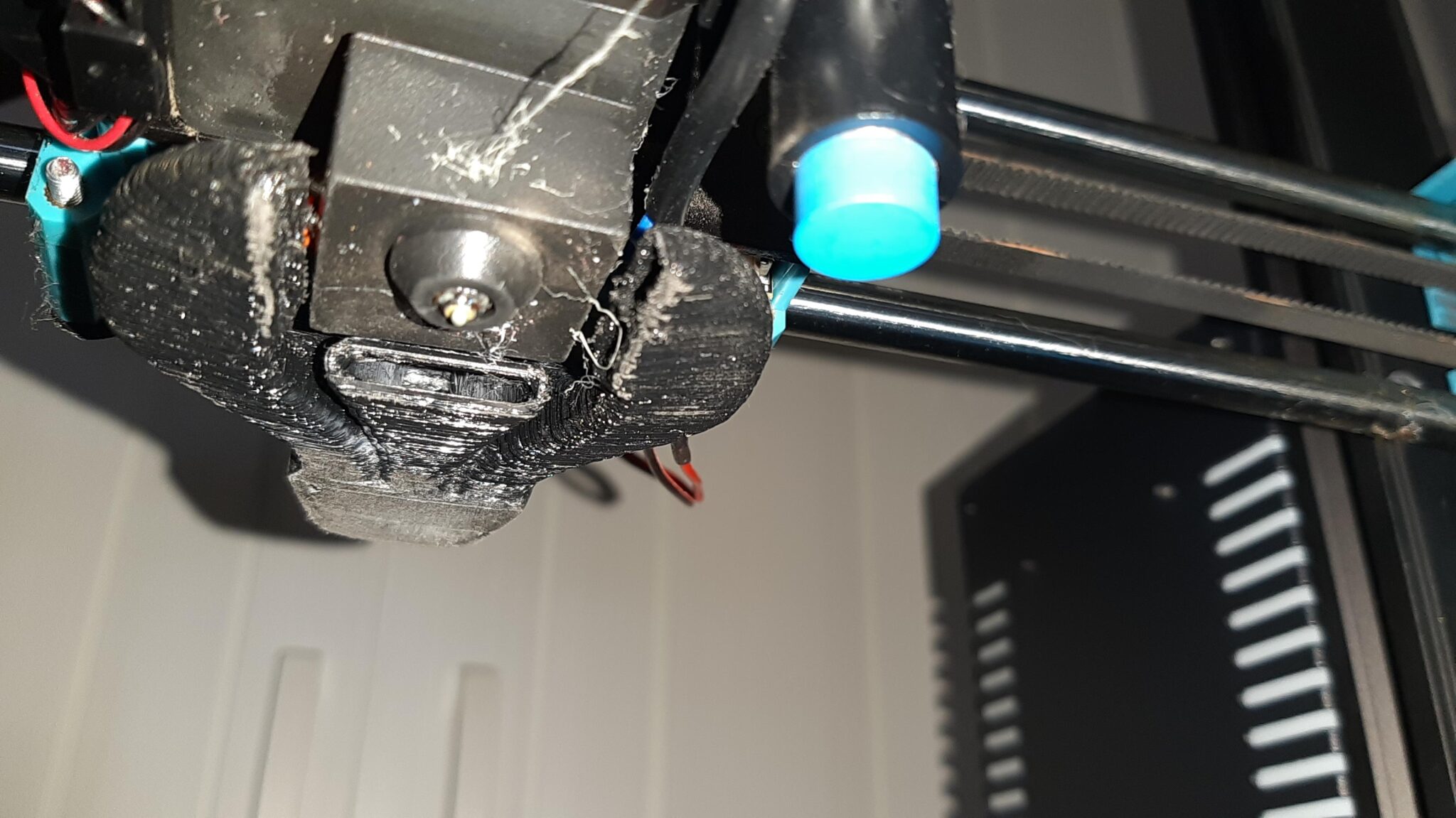

When I removed the blob, the old air duct broke.

I searched Printables for a new duct and found this one: Nautilus.

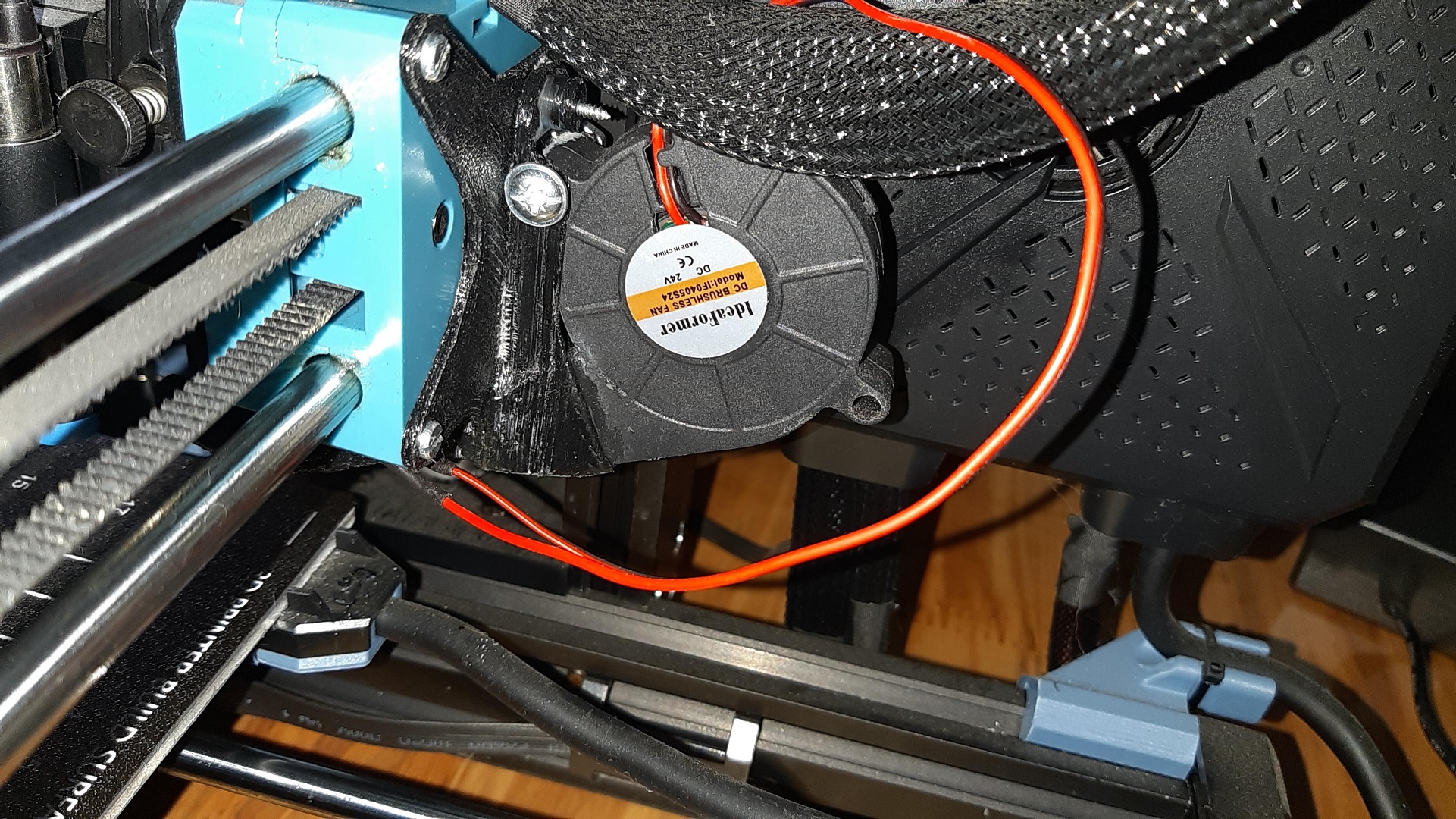

I’ve bought a new, stronger blower fan (5015 24v).

Then I printed the new duct (using nylon filament).

The printed duct is ugly (not very smooth) because I used wet nylon filament.

Then I glued the parts together. Firstly I used superglue, but it didn’t hold for long. Then I used 2-component epoxy glue.

I removed the old fan and attaching plate. Then I mounted a new fan and a duct. I used some random bolts to attach it to the extruder.

I had to cut wires and replace a connector. The connector that came with fan was too big. I reused the old fan’s conector.

Then I had to sand off the bottom (mostly remainings of epoxy), because it touched the bed when homing.

Now the fan works really well. I tested it during 5-hr PLA print and it went without problems.

I wanted to replace the original fan from the beginning, because it was mounted under the extruder, very close to the bed, and sucked the hot air. It started to fail and it was loud. The blob and broken duct was a push to replace it.

I even increased the speed of printing from 60 to 100mms and the new fan performed pretty well.

Nevertheless, I will print another duct bc I’m not sure how long this one will last. I fear of heat related warping.

Tags: #3dprinting #sv06 #sovol

Leave a Reply