(original post with nicer layout here)

#TPU material is one of my favourite materials for #3Dprinting. During the last year I’ve printed some usable objects for home improvement.

Why?

- it sticks to the plate really well

- it is soft and flexible

- it is weather and wear-resistant

- it looks good

- it doesn’t string (if there are not a lot of retractions or overhangs)

Material

I’m using Overture’s orange TPU.

Settings

I’m printing with the following settings:

- printer: Sovol SV06 with Marlin

- sliced with: Sovol Cura 1.7.2

- material set in slicer: Generic TPU 95A

- bed temp.: 60C

- nozzle temp.: 220C

- nozzle size: 0.4mm

- layer height: from 0.15 to 0.3mm

- speed: 40mm/s

- infill: 10% except if stated otherwise

- other settings: ‘arc welder’, ‘dynamic precision’ and ‘use adaptive layers’ turned on in Cura

- hardware settings: I’ve loosened down the screw (spring) that pushes against the filament at the extruder entry. Otherwise, the filament will get stuck in the extruder gears.

Practical cases:

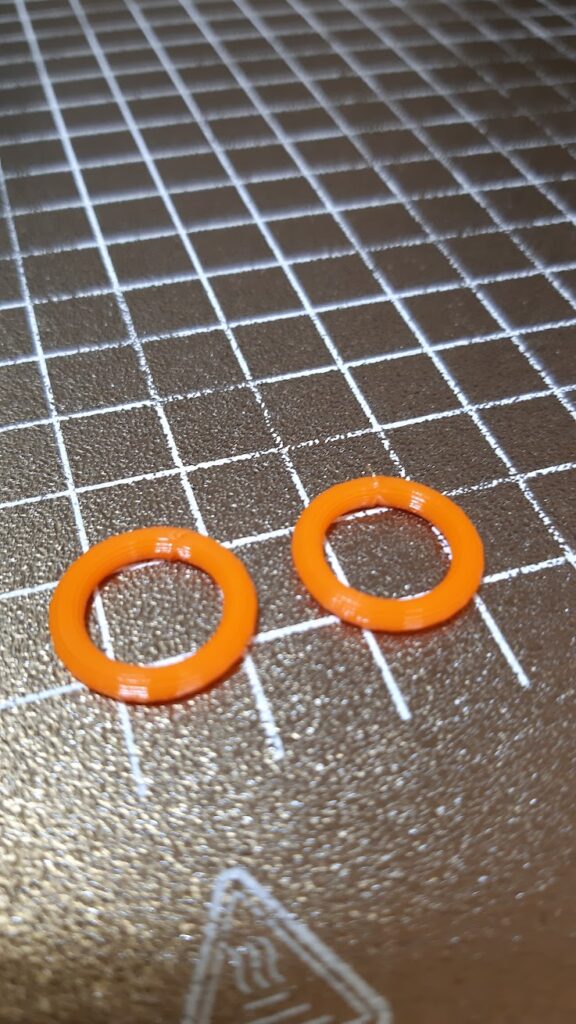

1. Gaskets

A rubber gasket for my garden hose connector broke. It took me several minutes (ok, a full hour and 3 unsuccessful attempts) to match the dimensions of the original gasket. TinkerCad has a strange idea for doughnut dimensions, so I had to do some trial-and-error.

I tried out the gasket, connected the garden hose and it doesn’t leak. I had to stretch it to fit it in the hose connector crack, but it acts as a rubber – it’s a tight fit.

The black gasket in the image right is the original one.

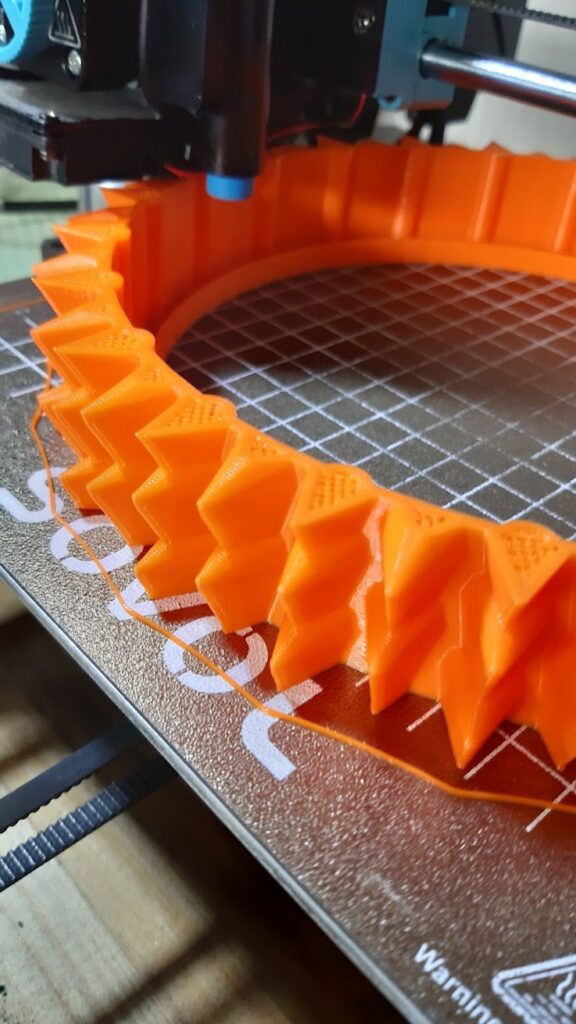

2. Lawnmower tyres/wheels

The original lawnmower (Worx Landroid M700) tyres wore out after a year so I had to replace them. New ones are around 60€. If I print them I use 400g of material, which is ~10€.

Last year I printed them with #PETG and #nylon.

PETG wheels wore in 4 months.

Nylon wheels were a bit better, but printing nylon is a PITA. It pops and cracks while printing (water) and I never managed to dry it. After it caught moisture (after a day of printing), it was impossible to dry it. It surprised me that nylon is somehow dimensionally unstable. When I printed the wheels, it was very difficult to slip them on the wheel. After few days, the tyres were too big and floppy and I had to use small screws to attach it to the wheels.

This year I decided to use TPU.

The bed of my printer (SOVOL SV06) is just big enough to fit one wheel.

This time I used 30% infill.

The original model of the wheels (by Oscar78) has cone spikes. The one you see on the left photo has wider spikes. I achieved this effect by turning on the setting ‘Make overhangs printable’ at 8 degrees before slicing in Cura. So no supports are needed and the spikes are not so pointy as in the original 3d model.

If they’re too pointy, they catch too many leaves.

Worx’s lawnmower with new slip-on TPU wheels.

It works much better now. It doesn’t slip on the hill and the turns are smoother.

Side effect: the spikes aerate the soil.

3. Filter enclosure for washing machine

Our #Bosch’s dishwasher (2002) microfilter enclosure disintegrated after 20 years.

Firstly, I printed it with PLA and … of course, it warped. PLA doesn’t like 55-60C and washing detergents.

This is the next attempt: I tried to print the same design with TPU, but it failed. If the object is tall, it starts skewing above ~5cm and the print fails.

I had to redesign the enclosure. I’ve split it in half.

Finally, both halves printed with TPU and assembled.

Infill: 100%.

I’ve checked it after 6 months, it didn’t warp and it holds the filter mesh in place.

4. Handle bar protectors

These are slip-on handle bar protectors. The Piaggio MP3 is quite heavy and I already dropped it once while standing.

My design, the 3D model is on Printables.

Brake handles got the protectors too. TPU is so flexible I could design it with a bit smaller hole. I could slip it on without problems and it holds in place for more than a year.

Moreover, the orange colour makes me a bit more visible in the traffic.

5. Pipes and connectors

IBC tank adapter, water tap (original model on Printables by draman87).

Why did I choose TPU? Because I lost the gasket and the TPU is flexible, so I don’t need a gasket between the printed part and the screw.

6. Door stoppers

This one doesn’t need a special comment. The door handle was hitting the radiator and TPU is flexible so… their encounter is soft and quiet now.

Leave a Reply